en

en

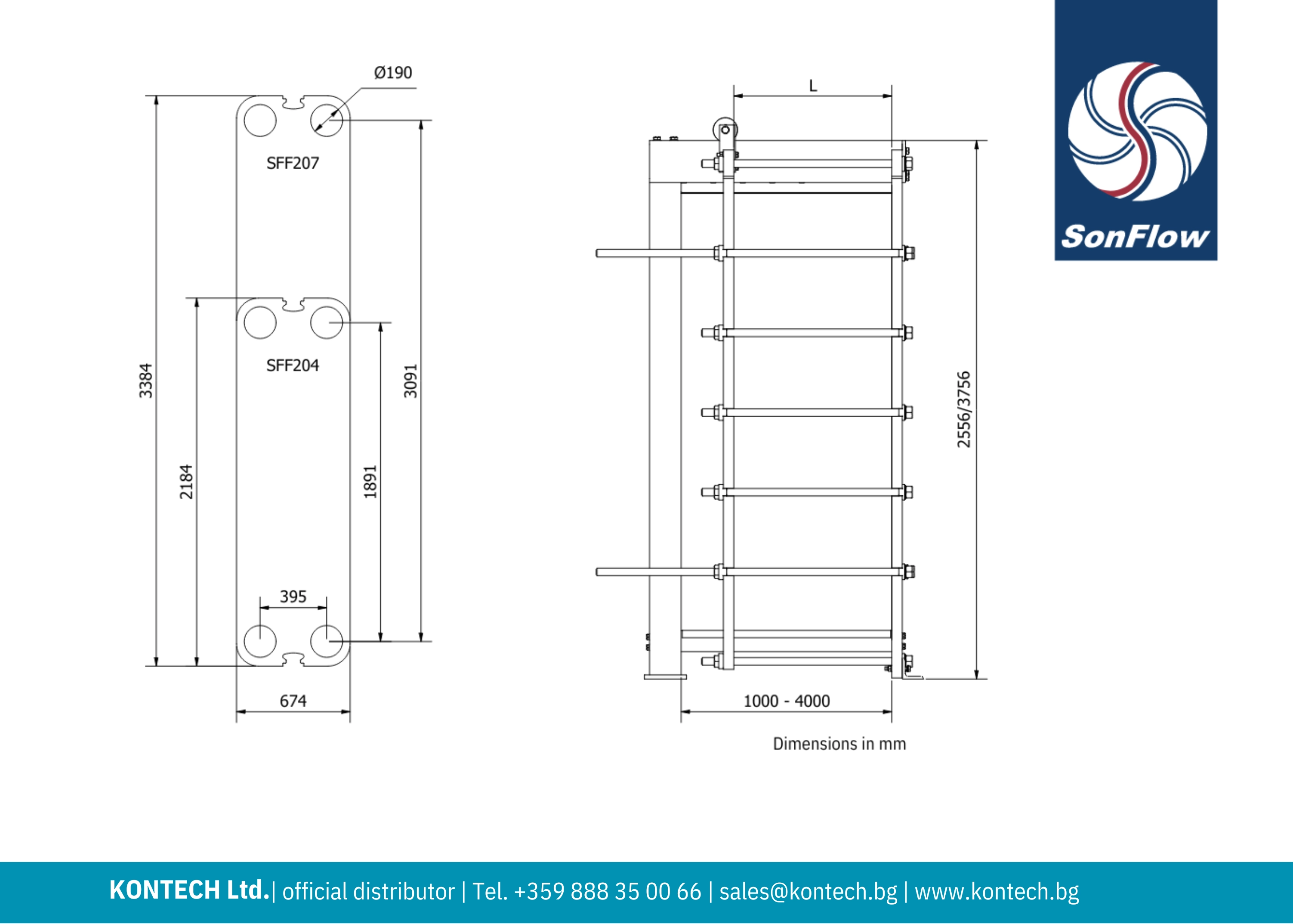

Heat Exchanger SFF204 and SFF207

SonFlow offers a wide range of Free Flow Plate Heat Exchangers for various market segments. Our SFF200 series is ideal for industries that handle liquids with fibers and solid particles, such as fruit juice and sugar production. Our plate heat exchangers ensure gentle treatment, even distribution of the medium, and high product quality.

Typical applications:

• Dairy/food/beverage industry

• Sugar industry

• Biogas industry

• Wastewater industry

• Pulp and paper industry

• Mining industry

Benefits:

• Designed for CIP cleaning

• Easy assembly

• Cost-affective

• Designed to combat fouling

• Clog resistant

• The inlet area is designed for optimal distribution and flow across the plate

Features:

Every detail is carefully designed to ensure optimal performance, reduced maintenance costs and decreased downtime:

• Compact design

• Lock gasket system

• Gentle product handling

• Suitable for products with solid particles

• Design pressure up to 10 bar

• Operating temperature: up to 180° C

• Fixed bolt head

• Lifting lug

• Lining

• Lock washer

Design pressure:

• Painted frames: 1.0 MPa

• Stainless steel frame: 1.0 MPa

• Max. differential pressure: 0.6 MPa

Construction standards:

• EN13445

• ASME sec VIII, Div. 1

Frame:

• Painted frame, RAL 5010 (available in other colours)

• Stainless steel

Connections:

• DN 200/8’’ flange in carbon steel or rubber lined

• According to all known standards

Plate material:

• AISI 304/316 and titanium

• Other materials available on request

Gaskets:

• The click on gasket – a glue less system for sealing

• Materials: NBR, EPDM and Viton

• Other materials available on request

Accessories:

• Drip tray

• Insulation jackets

• Safety cover

• Assembling spanner

• Foundation feet